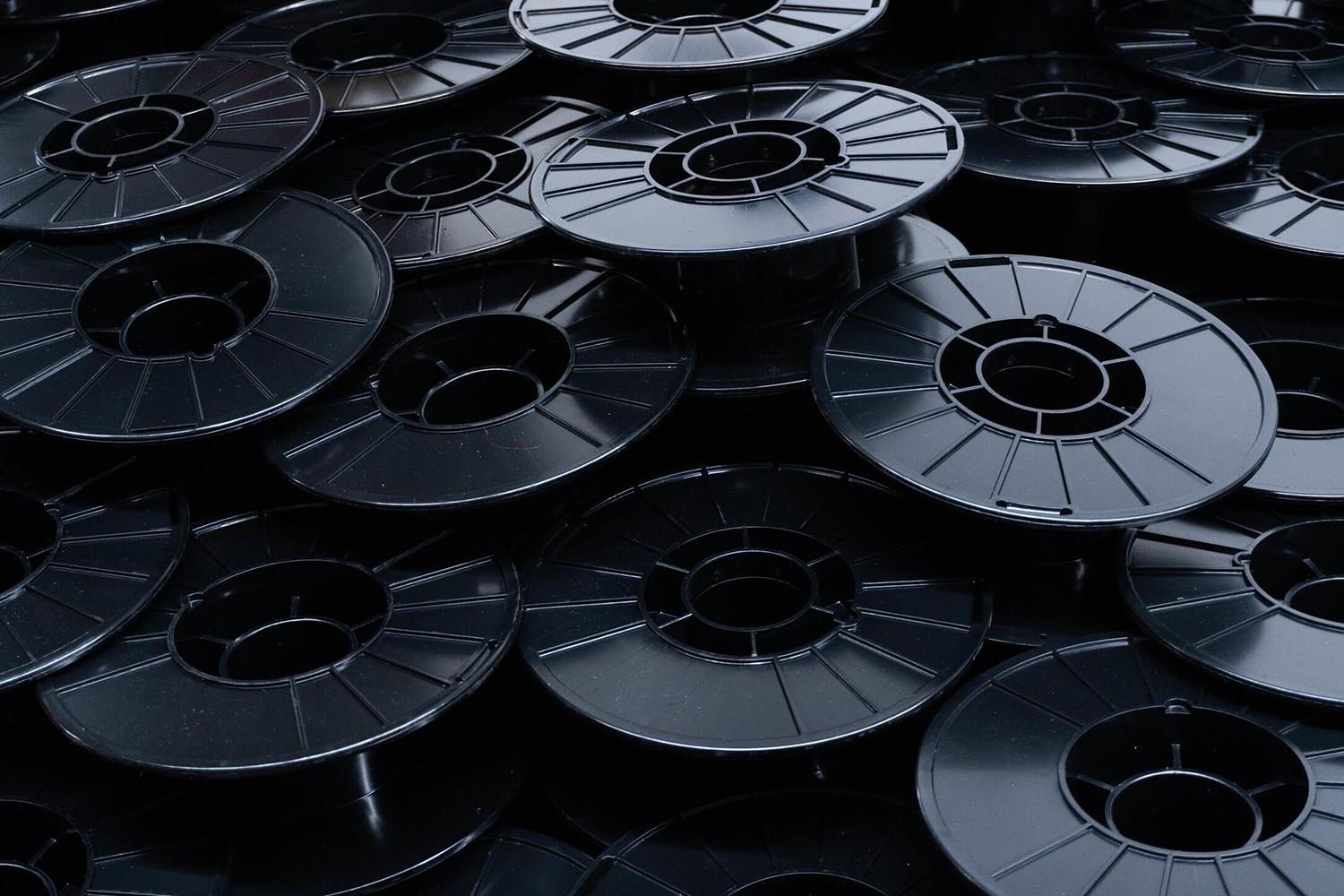

Stainless Steel 316L

Highly corrosion-resistant grade of austenitic stainless steel with great mechanical properties. Ideal for marine and chemical applications

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1875 cm³

- Density: 8.0 g/cm³

- Spool Type: BS300

Stainless Steel 308L

All-around stainless steel with adequate corrosion resistance and good mechanical properties.

Key Attributes:

- Diameter: 1mm

- Weight: 15 kg

- Volume: 1875 cm³

- Density: 8.0 g/cm³

- Spool Type: BS300

Stainless Steel 17-4PH

A martensitic precipitation hardened stainless steel capable of achieving high hardness while offering excellent corrosion resistance. It is widely employed in the oil & gas, aerospace, energy and defense industries. Typical applications include pump impellers, pipes and valves.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1935 cm³

- Density: 7.75 g/cm³

- Spool Type: BS300

Mild Steel ER70S

Mild steel with adequate mechanical properties and high ductility. Easily welded and machined.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1923 cm³

- Density: 7.8 g/cm³

- Spool Type: BS300

MTool Steel H11

A chromium-based steel alloy, it's one of the most commonly used tool steels, thanks to its outstanding impact toughness. H11 is widely used for hot tooling applications, in the manufacturing of dies, and in aerospace applications.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1920 cm³

- Density: 7.81 g/cm³

- Spool Type: BS300

Titanium 64

High strength Alpha+Beta alloy with excellent fracture toughness, corrosion resistance and biocompatibility. Widely used in aerospace, marine, chemical and biomedical industries

Key Attributes:

- Diameter: 1 mm

- Weight: 7.5 kg

- Volume: 1704 cm³

- Density: 4.4 g/cm³

- Spool Type: BS300

Nickel 718

HIgh strength nickle-super alloy with large working temperature range. Highly resistant against cracking while protecting well against corrosion.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1829 cm³

- Density: 8.2 g/cm³

- Spool Type: BS300

Nickel 625

A Ni-based superalloy with excellent mechanical properties at a wide range of temperatures. Among superalloys, Ni625 excels for its weldability, making it an ideal choice for cladding or repair of components working at high temperatures of requiring increased corrosion protection.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1829 cm³

- Density: 8.2 g/cm³

- Spool Type: BS300

Invar

This alloy gets its name thanks to its extremely low coefficient of thermal expansion, from -250°C up to about 200°C. This features makes it an ideal choice for measuring equipment, cryogenic applications and molds for the manufacturing of composite components for aerospace use.

Key Attributes:

- Diameter: 1 mm

- Weight: 15 kg

- Volume: 1851 cm³

- Density: 8.1 g/cm³

- Spool Type: BS300