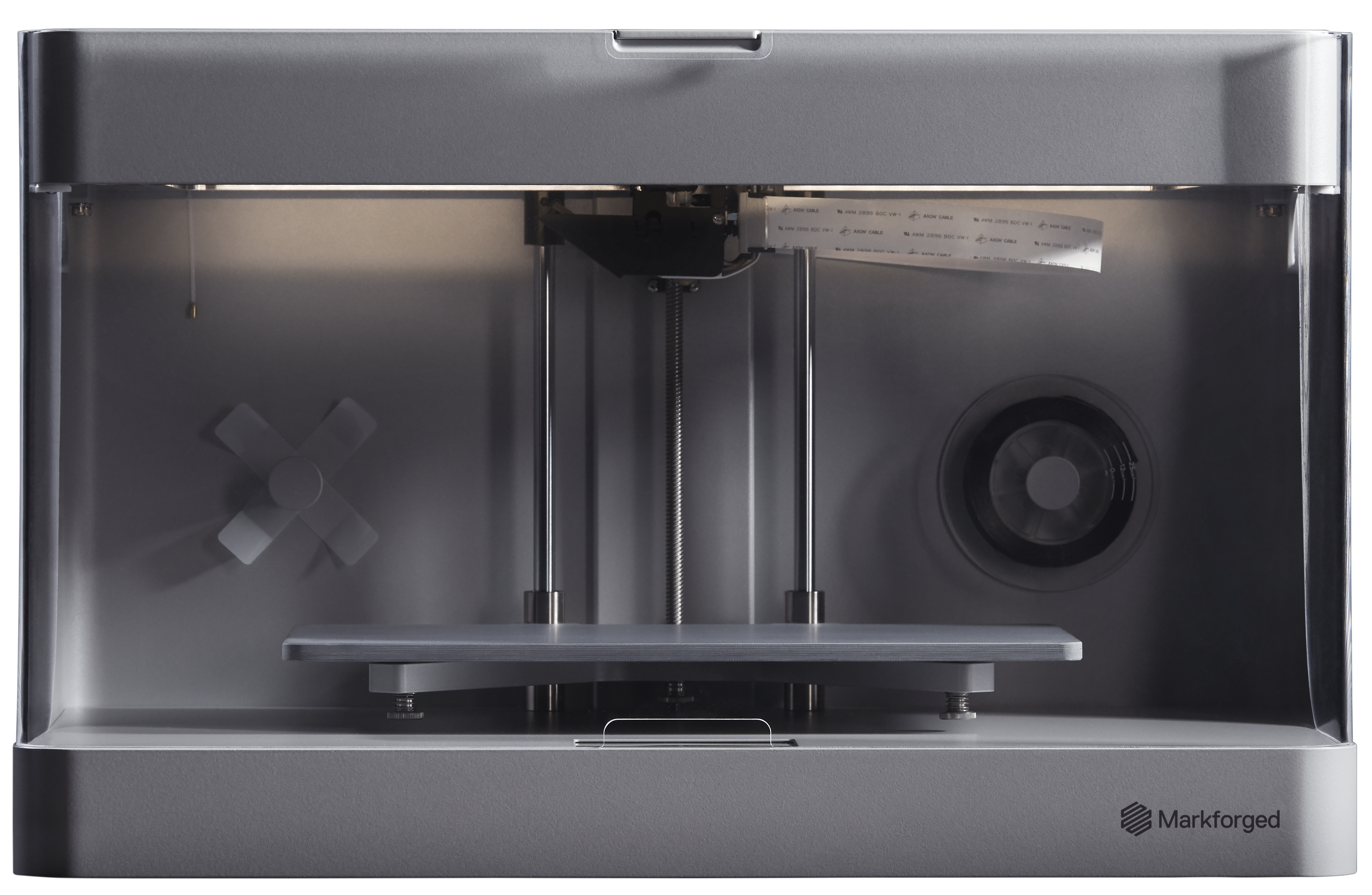

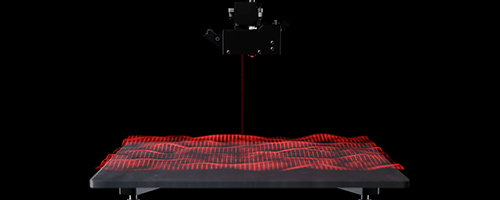

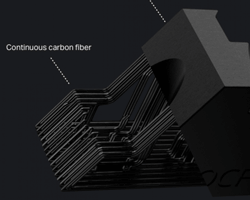

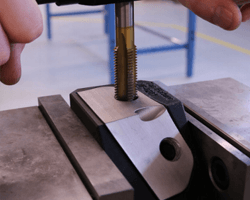

Continuous Filament Fabrication (CFF) Technology

CFF 3D printing technology uses two print nozzles to create composite parts, combining two materials into a single print. This unique process reinforces your parts with continuous fiber during the printing process, enabling you to have parts that are stronger, stiffer and more versatile than typical 3D printed plastic parts.

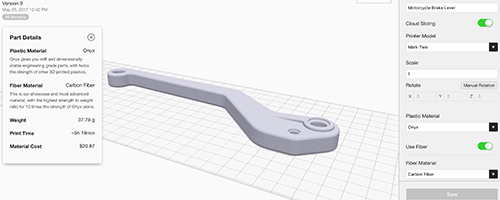

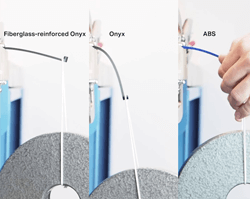

Onyx Filament

Every Markforged composite printer starts with Onyx filament which can be used for a variety of uses and can be mixed with continuous fibers to increase its strength. Even without reinforcement, this nylon contains chopped carbon fiber to give high strength, an excellent surface finish and heat deflection up to 293 degrees Fahrenheit.