Industrial Series: The FX20

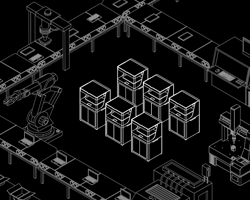

The FX20 Pairs Size and Throughput to Make Larger Builds at Incredible Speeds.

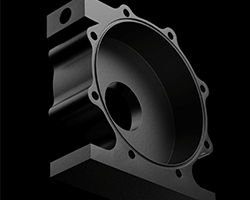

The FX20 is the largest and most precise machine Markforged has ever produced.

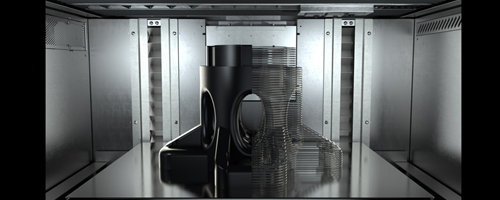

It features an 84L heated build chamber and massive, verified-flat vacuum bed with print sheets. The motion control system offers closed loop control through precision linear encoders, and is tuned to move the 3kg print head rapidly and accurately. FX20’s turbo mode builds parts faster than any Markforged machine, while new XL spools offer four times the material without spool changeover.

The FX20 is remarkably easy to use. It features a 7 inch touchscreen from which users can control every aspect of the printer. Automated calibration and leveling reduces operator input, while a wide variety of sensors give live feedback on machine performance. A material bay contains two active XL spools and can store two more with precise moisture control.

Printer Specifications:

- Heated Build Chamber

- Automated Calibration and Leveling

- Turbo Print Mode

- Build Volume: 20.6 x 15.7 x 15.7 in

- Print Resolutions: 50 - 250 Microns

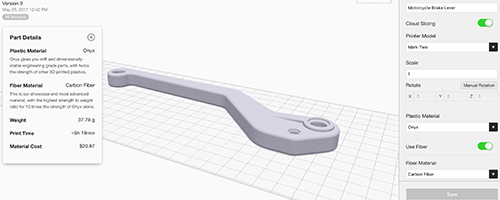

- Base Thermoplastic Materials: ULTEM™ 9085, Onyx, Onyx FR, Onyx ESD, Nylon White

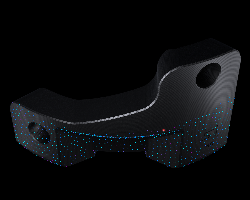

- Internal Fiber Reinforcement: Carbon Fiber, Fiberglass, Kevlar, HSHT Fiberglass

Learn more about the Markforged Industrial Series and composite 3D printing in our comprehensive online guide.