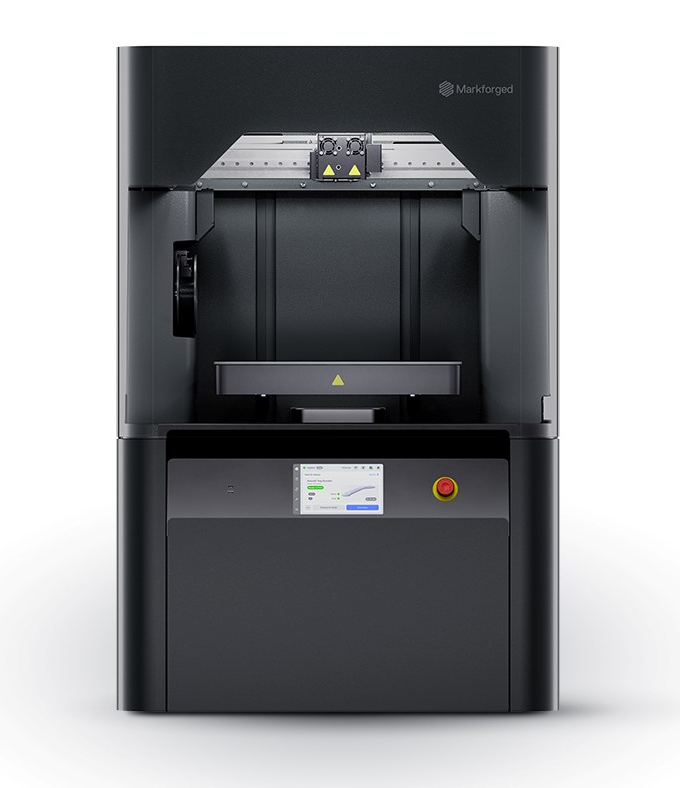

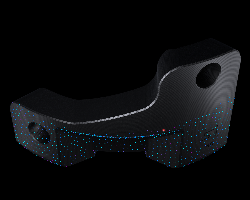

Industrial Series: The FX10

The World's First Industrial Metal and Composite Printer

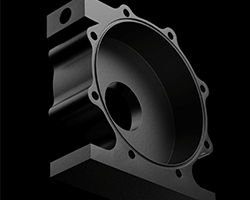

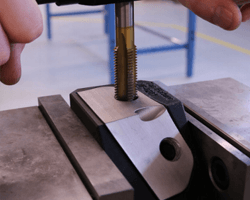

FX10 is the first industrial metal and composite 3D printer — the product of years of engineering innovation and technological advancement. Built on the success of the Markforged X7 and Metal X, FX10 quickly delivers strong, accurate tools and fixtures to your factory floor.

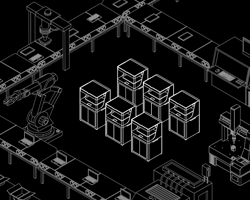

FX10 features a modular print system that enables users to swap between metal and composite print engines quickly and efficiently. All FX10s have composite capability, with metal capability as a purchasable add-on. Printhead-mounted optical sensors can verify the dimensional accuracy of parts and assess device health and performance. FX10 utilizes automatic calibration and material changeover, yielding a simple, low-touch user experience that mitigates the need for dedicated operators.

Printer Specifications:

- Automatic Calibration and Material Changeover

- Fused Filament Fabrication

- Continuous Fiber Reinforcement

- Build Volume: 14.8 x 11.8 x 11.8 in

- Print Resolutions: 125µm to 250µm (Metal = 127µm)

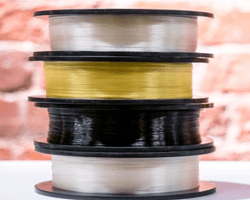

- Materials: Onyx, Onyx FR, Onyx ESD, Continuous Carbon Fiber, Continuous Carbon Fiber FR, 17-4PH Stainless Steel v2, 316L Stainless Steel